Contact Us

Address: Yuhua East Street, Zaoqiang County, Hengshui City, Hebei province

Phone: +86-15833836081

E-mail: js@jianshimake.com

Belt conveyor

- Commodity name: Belt conveyor

- Product Description

-

Scope of application

DTⅡ(A) fixed belt conveyor is a general-purpose series product, which can be widely used in metallurgy, coal, transportation, electric power, building materials, chemical industry, light industry, food and machinery industries, with a conveying bulk density of 500~2500 kg/m3All kinds of bulk materials and pieces of goods, the applicable environment temperature is -20~40 ℃.

For the working environment with heat resistance, cold resistance, corrosion resistance, explosion-proof and flame retardant requirements, special rubber conveyor belt shall be selected and corresponding protective measures shall be taken when selecting this series of products.

Product Specifications

1. Bandwidth Series

DTⅡ(A) type fixed belt conveyor takes its bandwidth as the main parameter, as shown in the following figure. Its bandwidth series, in line with the "belt conveyor" (GB/T 10595-2009) on the basic parameters and dimensions of the belt conveyor.

Bandwidth/mm 400 500 650 800 1000 1200 Code 40 50 65 80 100 120 Bandwidth/mm 1400 1600 1800 2000 2200 2400 Code 140 160 180 200 220 240 2. Product code

DTⅡ(A) fixed belt conveyor takes its bandwidth B, transmission roller diameter D and transmission roller allowable torque (sequence number) as product codes:

DT II (A)-Model (D-belt conveyor; T-universal; II (A)-new series)

B- -conveyor broadband. cm

D-diameter of rotating drum (excluding thickness of adhesive layer),cm

X-Torque sequence number of rotating drum (1,2,3,...)

For example, DT II (A)4025 · 1 represents a fixed belt conveyor with a bandwidth of 400mm, a diameter of 250mm and an allowable torque of 0.63kN · m.

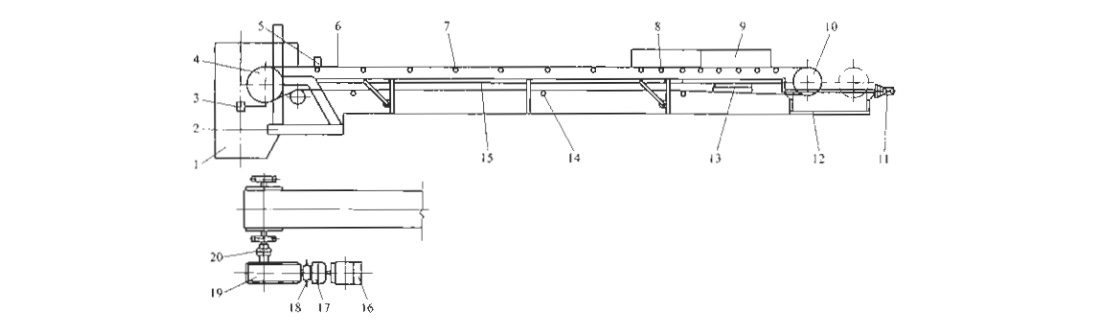

whole machine structure

1-head funnel; 2 head frame; 3-head sweeper; 4-driving roller; 5-safety protection device; 6-conveyor belt; 7-bearing roller; 8-stage punching roller; 9-guide chute; 10-reversing roller; 11-spiral tensioning device; 12-tailstock; 13-empty sweeper; 14-supporting roller; 15-intermediate return frame; 16-motor; 17-Wave power chimney; 18-Brake; 19-Reducer; 20-Coupling

See the table below for the classification code of each component.

Code Component Name Code Component Name A Turning drum B Redirection Roll Jane C Roller D tensioning device E Sweeper F Unloader G Roller H Roller skating group K Roller bearing seat L head funnel M Guide chute Q Drive device R Conveyor cover S Common components T Unloading truck U Reversible bin-matching belt conveyor V Water removal device W Water washing device X Telescopic head Y Pressure wheel JA Power transfer rolling bracket JB Redirection Roll Bracket JC Middle frame and leg JD Tensioning device support JF plough unloader funnel JQ Drive unit frame JT Middle bracket of unloading truck MF Plum coupling guard JD Tensioning device support YF Hydraulic coupling guard Typical configuration of the whole machine

Part Series

All kinds of components of DT II (A) belt conveyor are processed and manufactured according to "Special Figure for DT II (A) Belt Conveyor -2011", and fully conform to all kinds of national standards and industry standards effective before the end of 2010.

Conveyor belt

The varieties and specifications of the conveyor belt conform to the provisions of "fabric core conveyor belt belt and length" (GB/T4490-2009), "conveyor belt with rubber or plastic covering layer of general-purpose fabric core conveyor belt" (GB/T7984-2001) and "general-purpose steel wire rope core conveyor belt" (GB/T 9770-2001), see the following table.

Kind tensile strength

/N ·(mm · layer)-1delivery broadband 400 500 650 800 1000 1200 1400 1600 1800 2000 2200 2400 canvas bag CC-56 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Nylon bag Nn-100 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Nn-150 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Nn-200 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Nn-250 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Nn-300 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Polyester tape EP-100 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ EP-200 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ EP-300 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Steel cord core belt St630 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ St800 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ St1000 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ St1250 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ St1600 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ St2000 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ St2500 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ St3150 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ St4000 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ St4500 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ St5000 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ St5400 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ St6300 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Note:✔Indicates the current application range.

Transmission type and driving device

Transmission type and drive power parameters

Type of drive unit Power range/kW Remarks Y series motor coupling-reducer 1.1~3.7 When the power is ≤ 200kW, the voltage is 380V;

When the power is ≥ 220kW, the voltage is 3000V, 6000V and 10000VY series motor-hydraulic coupling · reducer 45~315 electric rolling drive 2.2~55 Other drive forms ≥ 355 User's own design Turning drum

The diameter and length of the driving drum shall conform to the basic parameters and dimensions of the drum specified in Belt Conveyor (GB/T10595-2009).

Bandwidth B Drum diameter 250 315 400 500 630 800 1000 1250 1400 1600 1800 400 ✔ ✔ ✔ 500 ✔ ✔ ✔ ✔ 650 ✔ ✔ ✔ ✔ 800 ✔ ✔ ✔ ✔ ✔ ✔ ✔ 1000 ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ 1200 ✔ ✔ ✔ ✔ ✔ ✔ ✔ 1400 ✔ ✔ ✔ ✔ ✔ 1600 ✔ ✔ ✔ ✔ ✔ 1800 ✔ ✔ ✔ ✔ ✔ 2000 ✔ ✔ ✔ ✔ ✔ 2200 ✔ ✔ ✔ ✔ ✔ ✔ 2400 ✔ ✔ ✔ ✔ ✔ ✔ Note: The rolling diameter is the nominal value without adhesive layer.

This series of transmission roller is divided into light, medium and heavy three types according to the carrying capacity. Among them:

Light: shaft and hub for single key connection of single plate welded cylinder structure;

Medium-sized: Uranium and hub are single plate welded cylinder structure with expansion sleeve connection;

Heavy-duty: The shaft and the hub are connected by expansion sleeves, and the simplified structure is cast-welded. There are two types of one-way shaft output and two-way shaft output.

The same diameter of the rolling Jane some also equipped with several shaft diameter and bearing center distance.

The surface of the transmission drum is all rubber surface, and its shape is left to the herringbone, right to the herringbone and rhombus. When users need smooth drive rolling, they need to indicate in the order form and do special order processing.

The rolling simplified bearing seat is lubricated by a pressure grease nozzle. If centralized lubrication is used, it shall be proposed at the time of ordering, and the manufacturer can configure the required nozzle separately.

Key words:

Get Quote

Free product manual, leave contact information can be obtained!

Related Products

Mobile telescopic bucket wheel stacker-reclaimer

Mobile:

E-mail:

Online Message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.